Do you want to customize wire harness?

Sign in/up

Checkout

FAQs

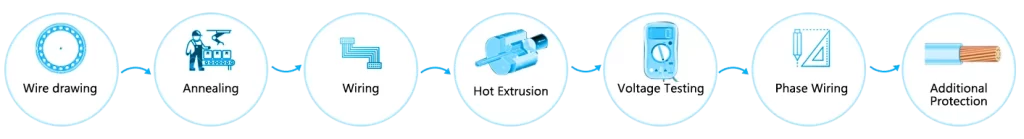

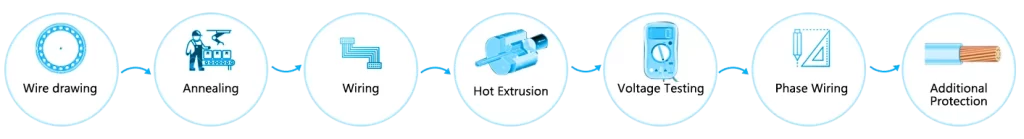

The Wire Harness Assembly process is one of the few remaining manufacturing processes that are more efficiently done by hand rather than automation. This is due to the variety of processes involved in the assembly.

DelightFire is a professional manufacturer of Wire Harnesses. We can custom types of wire harnessed with small and large MOQs at a competitive price for your project.

Also, we put a strong emphasis on quality. Our knowledge and expertise in the heart of our quality assurance process and promise of excellence to our customers. Our wide range of certifications stands as a testament to our quality and reputation. Those certifications include RoHs, SGS, UL, VDE, and CSA certificates.

$17.99 Original price was: $17.99.$16.99Current price is: $16.99.

$2.69 Original price was: $2.69.$1.69Current price is: $1.69.

$5.99 Original price was: $5.99.$5.39Current price is: $5.39.

$269.00 Original price was: $269.00.$239.00Current price is: $239.00.

$1.99 Original price was: $1.99.$1.29Current price is: $1.29.

$1.69 Original price was: $1.69.$1.29Current price is: $1.29.

$54.99 Original price was: $54.99.$39.99Current price is: $39.99.

$39.90 Original price was: $39.90.$36.90Current price is: $36.90.

$269.00 Original price was: $269.00.$199.00Current price is: $199.00.

$389.00 Original price was: $389.00.$269.00Current price is: $269.00.

$78.00 Original price was: $78.00.$75.00Current price is: $75.00.

$175.00 Original price was: $175.00.$170.00Current price is: $170.00.

$120.00 Original price was: $120.00.$115.00Current price is: $115.00.

AEROSPACE

AUTOMOBILES

MEDICINE

TELECOMMUNICATIONS

CONSTRUCTION

ELECTRONICS

HOUSEHOLD APPLIANCES

LIGHTING

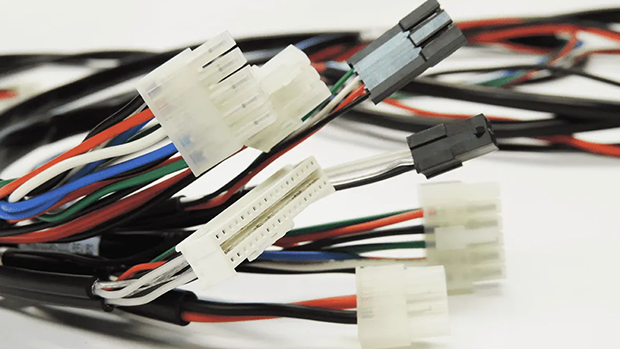

A wire harness is a common and effective tool for keeping multiple wires within a piece of equipment in order. On a more basic level, it’s the exterior covering,or sleeve, that encases and protects an inner conductor or bundle of conductors.

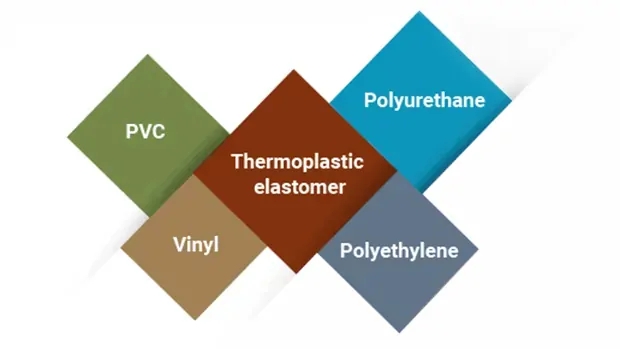

Wire harnesses can be made from anumber of durable materials.

Some of the most common include:

Most professionals consider wire harnesses and cable assemblies interchangeably. Using these multi-cable (or multi-wire) assemblies helps us with various applications and special projects and situations.

So, what exactly is a wire harness? A wire harness is an exterior casing that contains conductors inside it. Some inner conductors have separate insulation and protection sheaths, but sometimes, they need to provide fire protection to the inner conductors. It is also essential for critical cable organization, but it is much cheaper and time-saving.

Compared to many harnessing methods, wiring harnesses have a low cost because of their simple and effective designs. We can enhance all the interconnection supplies of the components using a standard cable harness.

There are many types of harnesses that you can use for various purposes, and we’ll assist you in selecting the best choice for your project needs. Also, if your requirements are unique or complex, we offer custom wire & cable tailored to your preferences.

Wire harnesses can be divided into two groups according to connectors and terminals.

Because connectors are required to perform various functions under different conditions, their design varies for each application, from connecting consumer products to medical devices, aerospace equipment, defense hardware, and automotive components. The design and scope of the connectors depend on the functionality of the device or appliance.

As buyers, the types of boundaries are different. Depending on the type of contact and the wire, the ends are available in different shapes, such as hooks, shovels, rings, quick release, barrels, balls, and flags. Each harness is unique and designed for a specific task with limitations and signal groups. Selecting the precise connection and terminal device for operation is critical for an utterly wireless function.

Almost all the home appliances we use have wires and cables for connectivity. Using harnesses, we can arrange those wire systems in an organized way according to each unique situation.

Wire harnesses can accommodate a wide range of applications up to 600 V (UL) or 3000 V (Military) and show excellent performance between -65 °C (-85 °F) and 250 °C (482 °F) temperature ranges.

A cable harness is a complete system designed explicitly for attaching multiple cables or wires rather than going out by hand and tying all the individual fibers together.

Wires are cut to length, folded, connected to a lever, or tied together. This tight, organized configuration allows in-line installation to reduce downtime and human error.

It enables technologists to install complicated cables in small or remote locations ordinarily challenging to access.

The customizing of cabling consists of dozens of overlapping cables running in multiple directions and at intersections. Because of this complexity in design, low-quality wires, particularly at end joints, can have several problems. These arrangements do not require any power. A hallmark of high-quality wire harnesses is their consistent and well-thought design and manufacture.

There are many choices of cable types for you to consider. With custom wire harnesses, we precisely manufacture the wire harness you need. Before selecting a wire harness, it is crucial to consider your project’s environment and physical conditions. Some of your wire harnesses options are shown below.

We take great pride in partnering with our clients. Our experts are available to help you to select your custom harnesses options. We recommend the best options for your specific applications through a well-oriented engineering process. The choice is yours, but we are here to ensure your selection is safe, durable, effective, and reliable.

Underwriters Laboratories (UL) is the US government’s authorized agency that performs safety, compliance, and functionality tests for products and processes. All our wire and cable harness products have UL certification, which guarantees our products’ higher quality. Our engineers can self-assuredly design your harness selection using these certified wires and cables.

Using products manufactured outside the plant or by third parties can be an issue, specifically as it can be hazardous to introduce an inappropriate product into your supply chain. Our wiring traceability platform assists you in reducing this risk by providing you with the information you need to receive only wire harnesses that have been tested and certified by one of the most reliable foundations in the industry.

High-Performance Materials

Wire harnesses can be used as insulation and protection coatings for the inner components for organizing purposes. The followings are some of the widely used materials for wire harnesses. It is essential to select the right material for your application:

When selecting the right material, it is important to consider voltage, operating temperature, and moisture parameters. Otherwise, some conditions may affect the performance of these materials.

The following factors also can affect the performance of wire harnesses designs:

Wire & cable harnesses are the ideal options for any interconnection requirements in many industries.

Wire harnesses are used in almost any household appliance, commercial or industrial equipment, tools, gear, machinery, hardware, and household products that transmit or transfer electronic or electrical information.

A practical harness is an essential, if not indispensable, component of this device. Tube nets are manufactured in various sizes and settings with regard to unit applications and environmental needs.

These procedures can be used anywhere, from temperature-controlled buildings or homes to severe external climates with extreme temperatures or even in sea-level marine environments.

Following industries use wire harnesses, especially to increase efficiency and secure workplace safety:

Wire harnesses are widely used in many fields and industries because of the benefits of their use. Some of these benefits include:

Simple and effective designs can enhance the benefits of wire harnesses. Sheaths protect wires and cables against hazardous substances and reduce fire hazards. Connectors, lacing, clips, and other organizing methods can increase a workspace’s efficiency by reducing the amount of space required from unorganized wiring. It is ideal for machines and equipment with intricate and advanced wiring systems to use wire harnesses because of many of the above benefits.

One of the major issues of wire harness testing is sustaining control over the testing process. The cable testing procedure is generally not completely automated. Technicians connect and disconnect the wiring from the test device manually. Once it has been checked, it has to be classified as faulty or safe, and the technician must separate the faulty from the safe wiring harness.

The technician may not accurately separate faulty wiring harnesses, initiating serious difficulties with the subsequent flow. Another possible issue occurs when the technician does not let the test be concluded and releases partially verified cable harnesses from the test element. Choosing the incorrect test platform is also a potential issue.

We can use a test board to check the electrical functionality of a wire harness. We can pre-program the required electrical parameters into a test board. Then we can connect the harness to the test board and check the functionality separately or in compound amounts.

The fixture clip is a mechanism that clamps the connector in position when the cable harness is checked. Every fixture clip method uses an automated bolting feature that works when the connector is attached to a bracket.

Once all tests have been completed, an electrical solenoid is linked to disconnect after the test. It is effective to apply fixture clips bolted and affixed in place by automated latches and open when the electrical solenoid is turned on. This ensures that the clip stays locked even in a power failure.

Our designs vary from basic and simple tasks, such as a basic terminal attached two-wire bound, to highly complex and advanced designs containing various connectors, conductors, sheathing, terminations, grommets, over-molds, and strain relief. This can be a highly complex task most of the time, but do not worry! Our well-trained engineers are able to design your wire harness requirements at a lower cost and higher efficiency.

LOOKING FOR A CUSTOM WIRE HARNESSES MANUFACTURER

FOR YOUR PROJECT

Need a Quote for Custom Wires Harnesses for Your Device? Talk to Our Wire Experts Today.

@2012 - 2025 DelightFire. All Rights Reserved. | PRIVACY POLICY